My Projects

I’m proud to show off some of the projects I have worked on because each one represents my continuous growth in learning and loving engineering. I hope you have as much fun reading about them as I did designing and building them.

Red

Red is the robot that I designed in my final year in FRC on Team 668, the Apes of Wrath. The robot was designed in OnShape and manufactured in-house during our 6 week build cycle. As the mechanical design lead, I personally designed the majority of the drivetrain and mechanisms of Red. I also lead the manufacturing team, while teaching and performing hands-on tasks including writing g-code, creating engineering drawings, and using our custom-built CNC routers.

Features Include:

6 wheel drivetrain with drop-center; 17 ft/sec top speed

Rotating arm with compliant wheels for “touch-it, grab-it” intake

Conveyor system with simple tensioning system

Custom multi-stage gearboxes for arm and drivetrain

Open top to intake balls dropped from above

Our first scheduled competition was the Utah Regional. During the event, Red was able to quickly intake and deposit 5 balls at a time into the scoring zones. It won the prestigious “Excellence in Engineering” award. Unfortunately, the season was then cut short as a result of Covid-19.

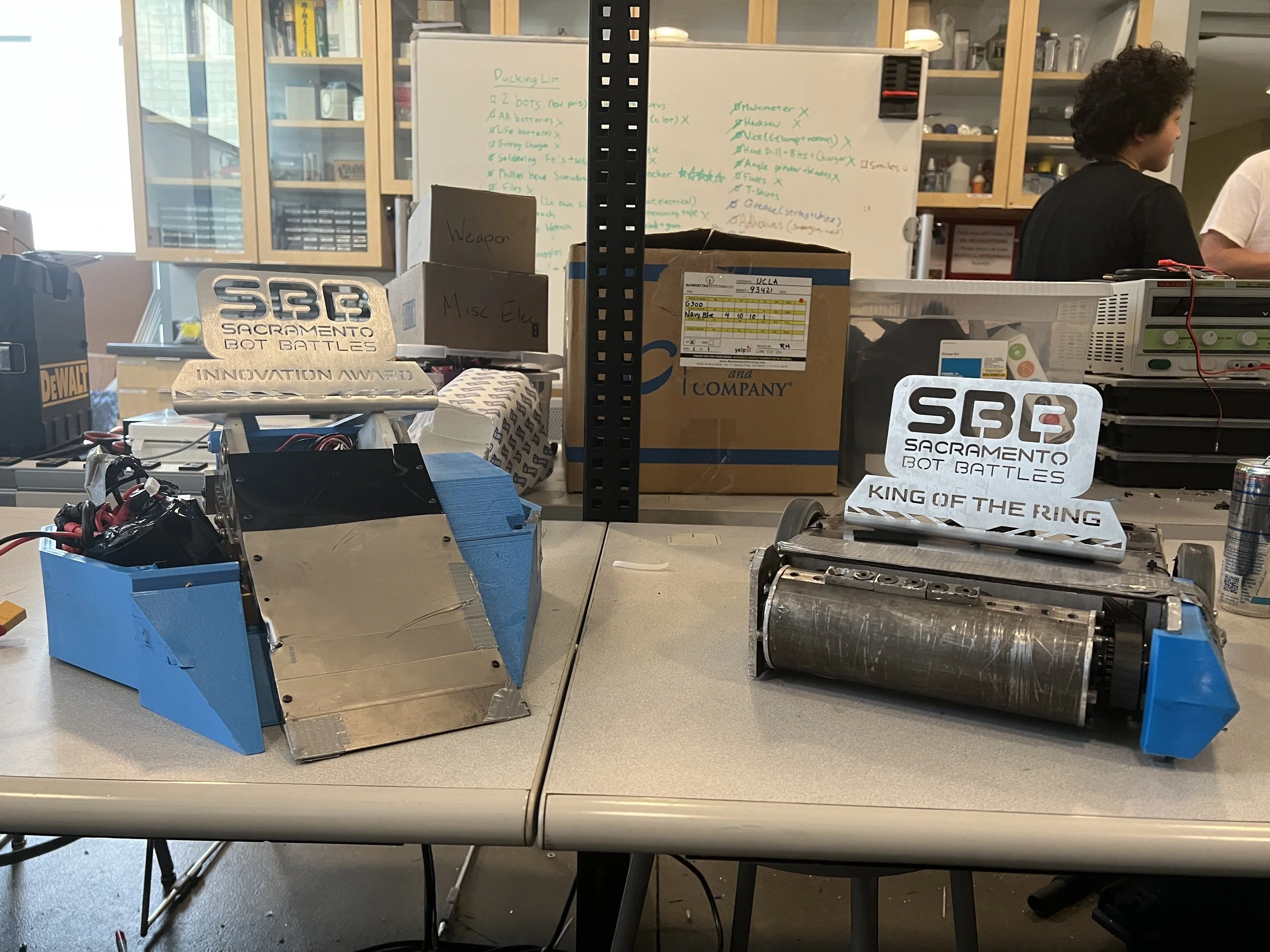

Cheddar

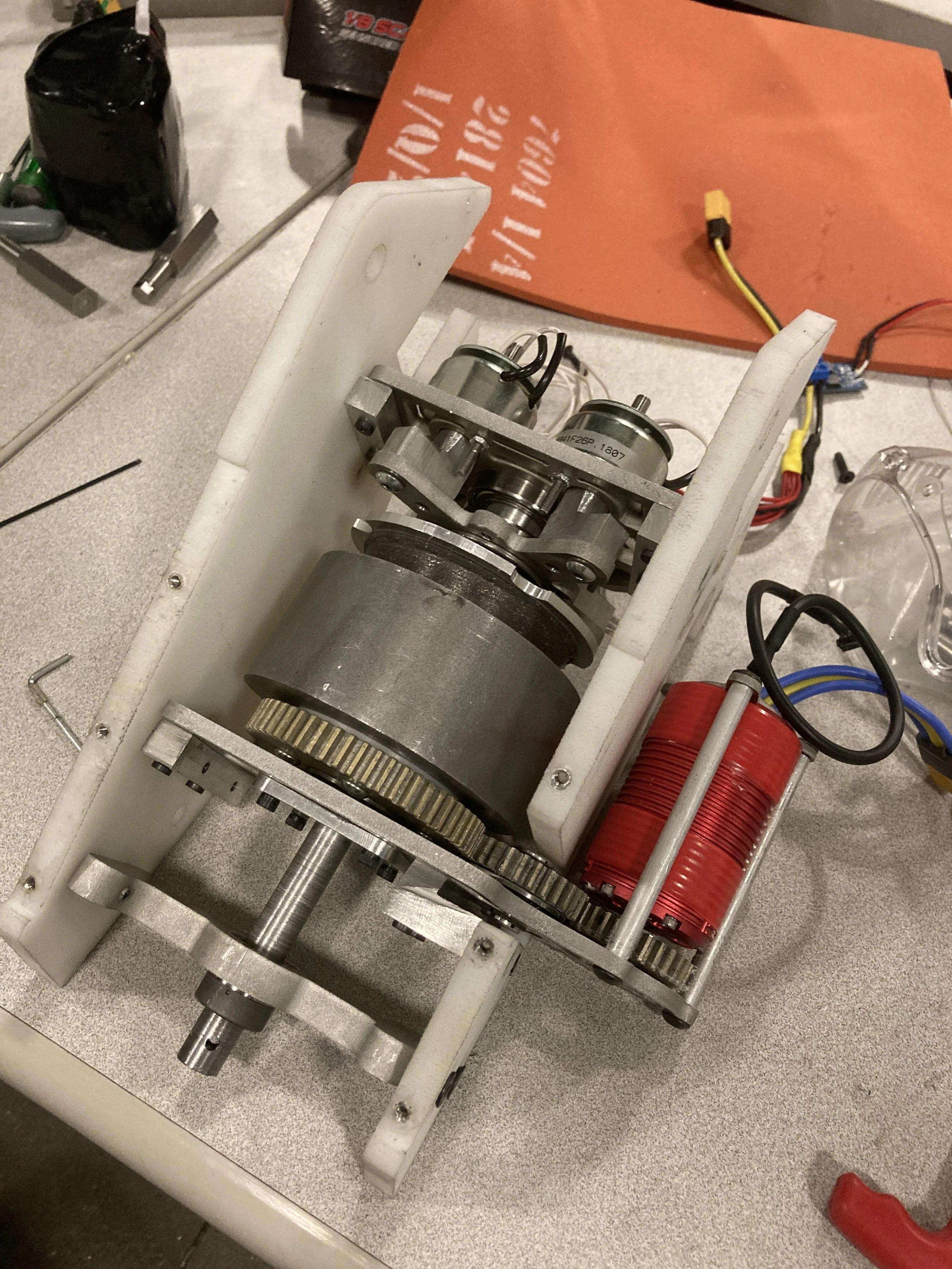

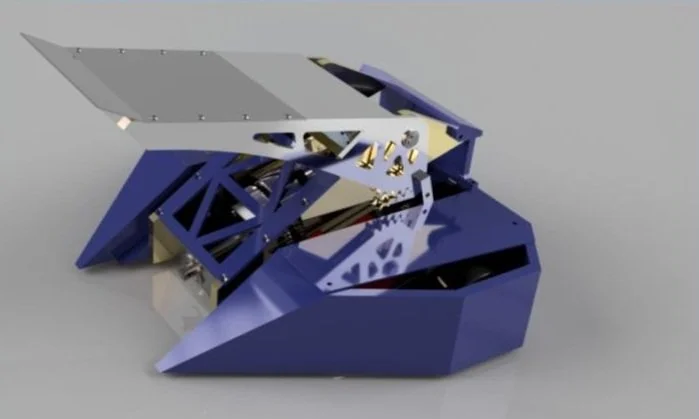

Cheddar is the robot I designed for Battle Bots (“Combat Robotics”) at UCLA. The robot was designed to compete in the 15 lb division, and we decided to take on a very mechanically ambitious project. As the weapon system lead, I lead the team through designing, manufacturing, and assembling the flipper system.

We competed at the annual Sacramento Bot Battles competition, where we took home the distinguished “Innovation Award” for our creative one-of-a-kind flipping mechanism.

As mentioned above, the flipping mechanism was a complicated, yet rewarding challenge.

Here’s how it works:

Weapon motor spins a geartrain, which spins up the 3 lbs steel flywheel to store kinetic energy

Motor enters free-spin and 4 solenoids (200 N ea.) activate a tapered friction clutch

Hollow, splined tube inside the clutch starts spinning, with string going through the middle

The string starts spinning while attached to tube and to a rack and pinion

String twists, reducing it’s length, thereby pulling the rack and pinion forward; Rotational to translational

“Pinion” is the flipper which flips opposing robots

Other features:

TPU armor and electronics mounting for vibration absorption

High-speed, high maneuverability 2-wheel drivetrain

Super-Mileage Vehicle

In 2023, I worked on a car to compete in the EV urban concept class for the Shell-Eco Marathon. Compared to traditional super-mileage vehicles, the urban class to have functions that a such as a windshield wiper, horn, brake lights, trunk, and more. As the Steering Lead, I was primarily responsible for designing, manufacturing, and assembling the steering and braking systems.

Features:

Centralized 5-bar steering system using Ackermann steering

Steering knuckles with adjustable camber, toe, and caster; Measure using sniper alignment tool

Diagonal, 2-cylinder hydraulic braking system with flexible brake line

Ergonomic Bruin-shaped foot pedal

Custom, in-house chassis mold and prepreg fiberglass layup

Custom steering-wheel PCB and steering wheel

We competed at the Indianapolis 500 Motor Speedway. After a week-long event, we were awarded with 3rd place, the “Mechanical Innovation Award”, and the “Data and Telemetry Award”, resulting in a prize total of $12,000.

Vector

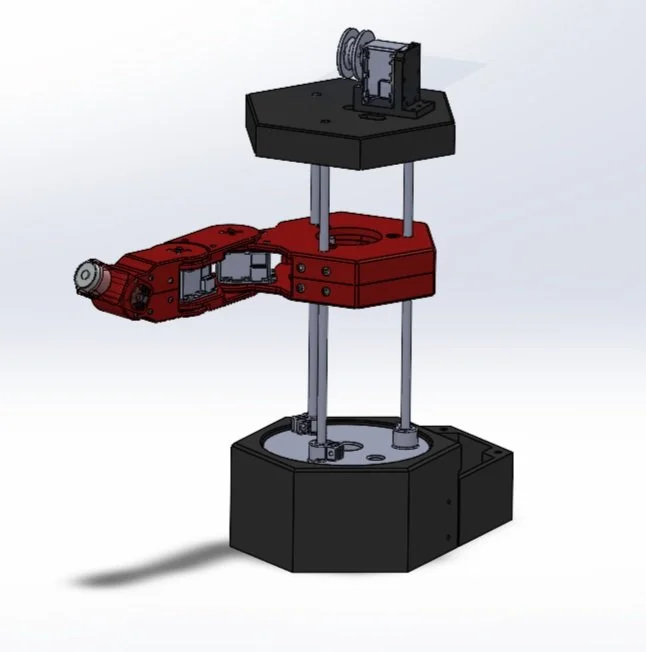

As a 4th year ME student at UCLA, I built a robot to play Connect-4. This robot was designed, built, and tuned over the course of 4 weeks as part of a project for a forward and inverse kinematics class. I designed the carriage in SolidWorks. In addition, I programmed the robot, which includes an intuitive user-interface using Matlab.

Features:

5 DOFs (4 rotation, 1 translation); All servo-controlled

Lazy-Susan in bottom box

Single-stage vertical elevator

Switch activated electromagnet

Custom 3D printed Connect-4 pieces with embedded metal

Collision prevention and acceleration control

User-friendly interface that allows playing as or versus the robot with game-tracking for illegal move and win-clause detection

William

My senior design project at UCLA was a boomerang throwing robot.

There’s always more to look forward to as an engineer - new challenges to tackle, new complex mechanisms to design, and new ways to find inspiration. Here’s what I’m working on right now:

TBD